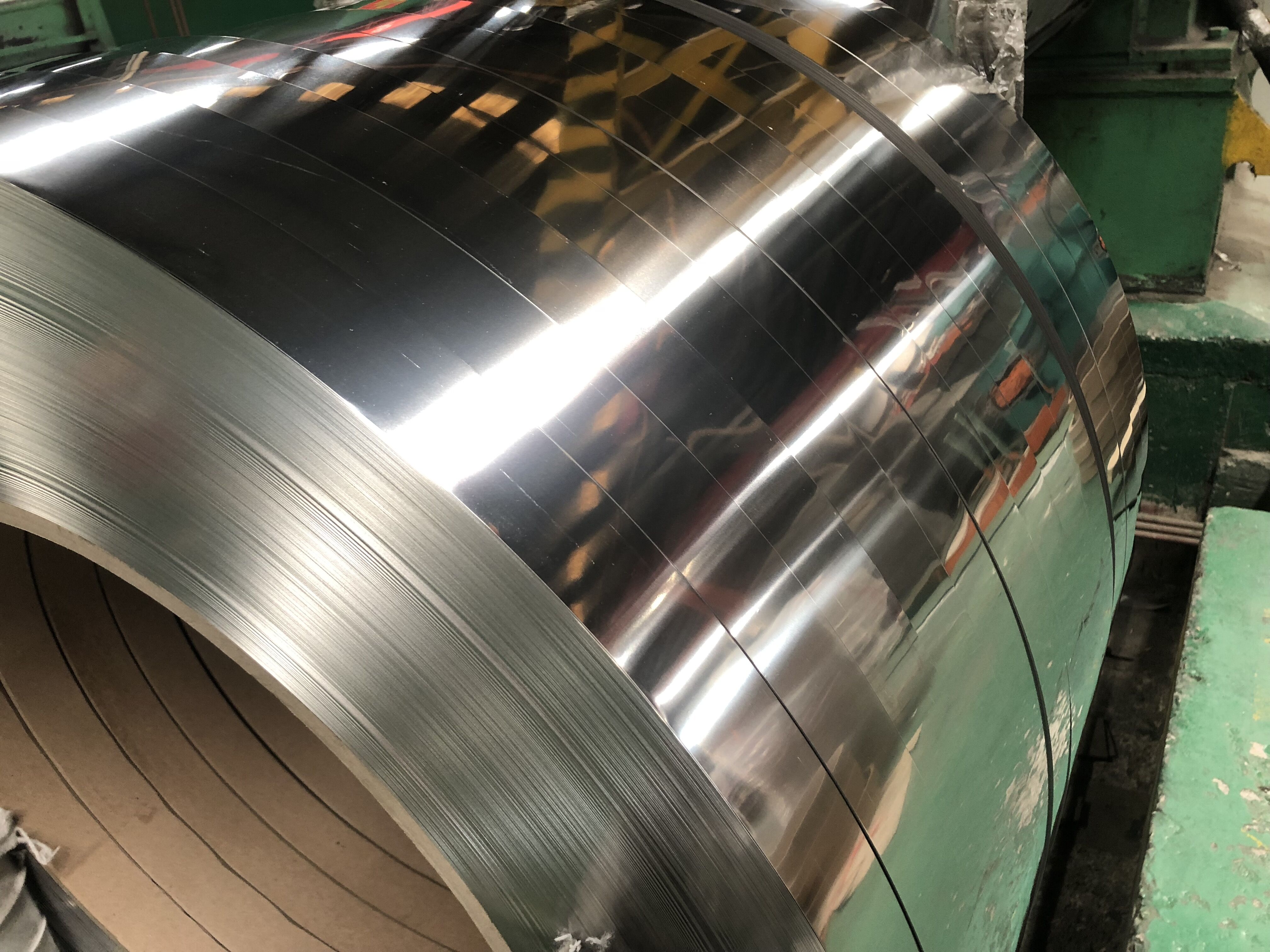

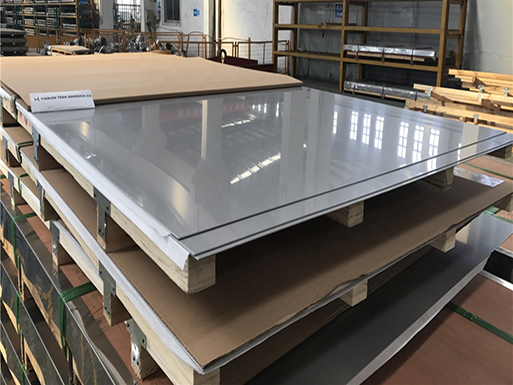

We are committed to provide our customers the most complete system of stainless steel products.

We warmly welcome your arrival and look forward to cooperating with you!

The steel grade is generally stabilized with tantalum or titanium to avoid intergranular corrosion after welding. This steel grade is particularly suitable for use in a variety of water treatment plants.

The 444 steel grade is a high-alloy ferritic stainless steel. Compared with the common steel grade SUS430: 1. The chromium content is about 1.0% higher, and the alloying element molybdenum (Mo) is added, so the steel has good pitting resistance. Corrosion resistance, stress corrosion resistance, its corrosion resistance is better than SUS304 and SUS316 in some fields. 2. Adding stabilizing elements such as titanium (Ti), niobium (Nb), zirconium (Zr), so the steel has Good resistance to intergranular corrosion and high temperature oxidation resistance.

Grade and Main Chemical Composition%

| Grade | C | Si | Mn | P≤ | S≤ | Cr | Mo | Ni | Other |

| 444 | ≤0.025 | ≤1.00 | ≤1.00 | 0.04 | 0.015 | 17-20 | 1.8-2.5 | – | – |

Mechanical Properties

| Grade | YS(Mpa) ≥ | TS (Mpa) ≥ | El (%) ≥ | Hardness(HV) ≤ |

| 444 | 300 | 420 | 20 | 217 |

The steel can be welded by welding ordinary stainless steel, and is particularly suitable for food processing equipment, heat exchangers, hot water tanks, water storage tanks, solar collector panels, and the like. Compared with other stainless steels, the steel is the only one that is magnetic. In view of this, the steel is not suitable for use in sensitive electronic equipment and aviation equipment that is susceptible to electromagnetic waves and magnetic interference.