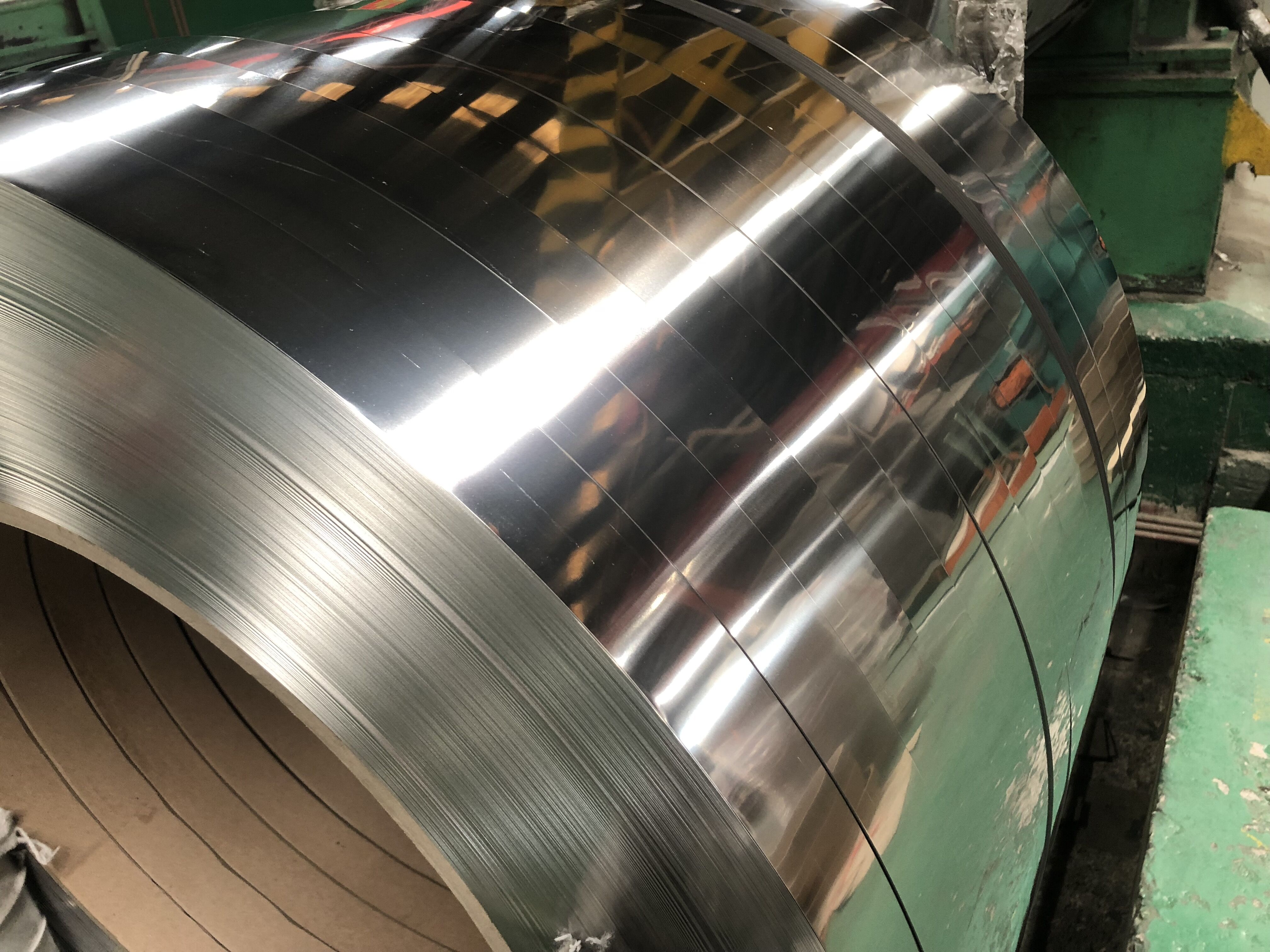

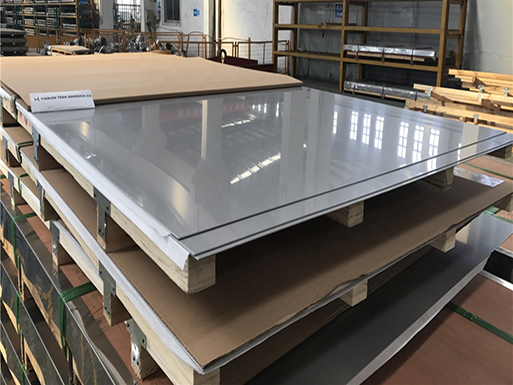

We are committed to provide our customers the most complete system of stainless steel products.

We warmly welcome your arrival and look forward to cooperating with you!

GB:022Cr17Ni12Mo2 TOCT :03X17H14M2

DIN:X2CrNiMo18.10 NF:Z2CND17.12

JIS:SUS316L ASTM/AISI:316L KS:STS316L

BSEN:1.4404 IS:02Cr17Ni12Mo2 BS:316S12

316L has a wide range of applications in the chemical industry due to its excellent corrosion resistance. 316L is also a derivative of 18-8 austenitic stainless steel with 2 to 3% Mo added. On the basis of 316L, many steel types are also derived. For example, 316Ti is derived after adding a small amount of Ti, 316N is derived after adding a small amount of N, and 317L is derived by increasing the Ni and Mo contents.

Most of the existing 316L on the market is produced according to the American standard. For cost reasons, steel mills generally rely on the Ni content of the product to the lower limit. The American standard stipulates that the Ni content of 316L is 10-14%, and the Japanese standard stipulates that the Ni content of 316L is 12-15%.

Grade and Main Chemical Composition%

| Grade | C | Si | Mn | P≤ | S≤ | Cr | Mo | Ni | Other |

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16-18 | 2 | 10 | – |

Mechanical Properties

| Grade | YS(Mpa) ≥ | TS (Mpa) ≥ | El (%) ≥ | Hardness(HV) ≤ |

| 316L | 200 | 480 | 50 | 180 |

316L application area: welded parts and equipment for thick section sizes, such as petroleum, fertilizer, paper, and materials for the atomic energy industry. Such as containers, towers, pipes, etc.