We are committed to provide our customers the most complete system of stainless steel products.

We warmly welcome your arrival and look forward to cooperating with you!

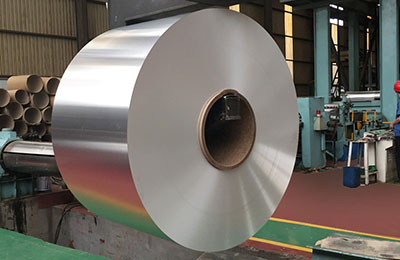

3003 aluminum alloy is an alloy in the wrought aluminum-manganese family (3000 or 3xxx series). It can be cold worked (but not, unlike some other other types of aluminum alloys, heat-treated) to produce tempers with a higher strength, but a lower ductility. Like most other aluminum-manganese alloys, 3003 is a general-purpose alloy with moderate strength, good workability, and good corrosion resistance. It is commonly rolled and extruded, but typically not forged.

| Grade | 3003 |

| Temper | all available, H1X, H2X, H3X, O, HXXX |

| Coil ID | 75mm, 150mm, 200mm, 300mm, 400mm, 508mm or negotiable |

| Coil OD | per customer’s request |

| Thickness | 0.20-8.0mm |

| Width | 8-2400mm |

| tolerance | +/-2% |

| Alloy or not | non-alloy/pure aluminum |

| Standard | JIS, AISI, ASTM, GB, DIN, EN |

| Certification | ISO |

| Surface | powder coated, anodized polishing, mirror finish, diamond , tread, brushed, wood grain, stucco embossed |

| Property | anti-corrosion, heat resistant |

| Production process | cold rolled |

| Application | storage device, decoration, pressure vessels ,etc |

| Core | paper core |

| Coil weight | 2~4 tons |

| Origin | China mainland |

| Payment | TT,LC |

| Package | covered with a layer of plastic film and cardboard, packed on the wooden pallets, bound with iron belt, loaded in the containers. |

| Delivery | 15~30 days |

| Grade | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Al |

| 3003 | 0.600 | 0.700 | 0.05-0.2 | 1.0-1.5 | – | – | – | 0.100 | remains |

As a wrought alloy, it is not used in casting. It is also commonly used in sheet metal applications such as HVAC, condenser, radiator, evaporator, heat shield, gutters, downspouts, roofing and siding.